Our Turning Department

Welcome to our full-service turning department. Equipped with 6 multi-axis CNC machines and a team with over 100 years of experience, there is no job too complex for us. We have proudly delivered parts for our customers in the Military, Aerospace, Transportation, Medical, and Mining industries.

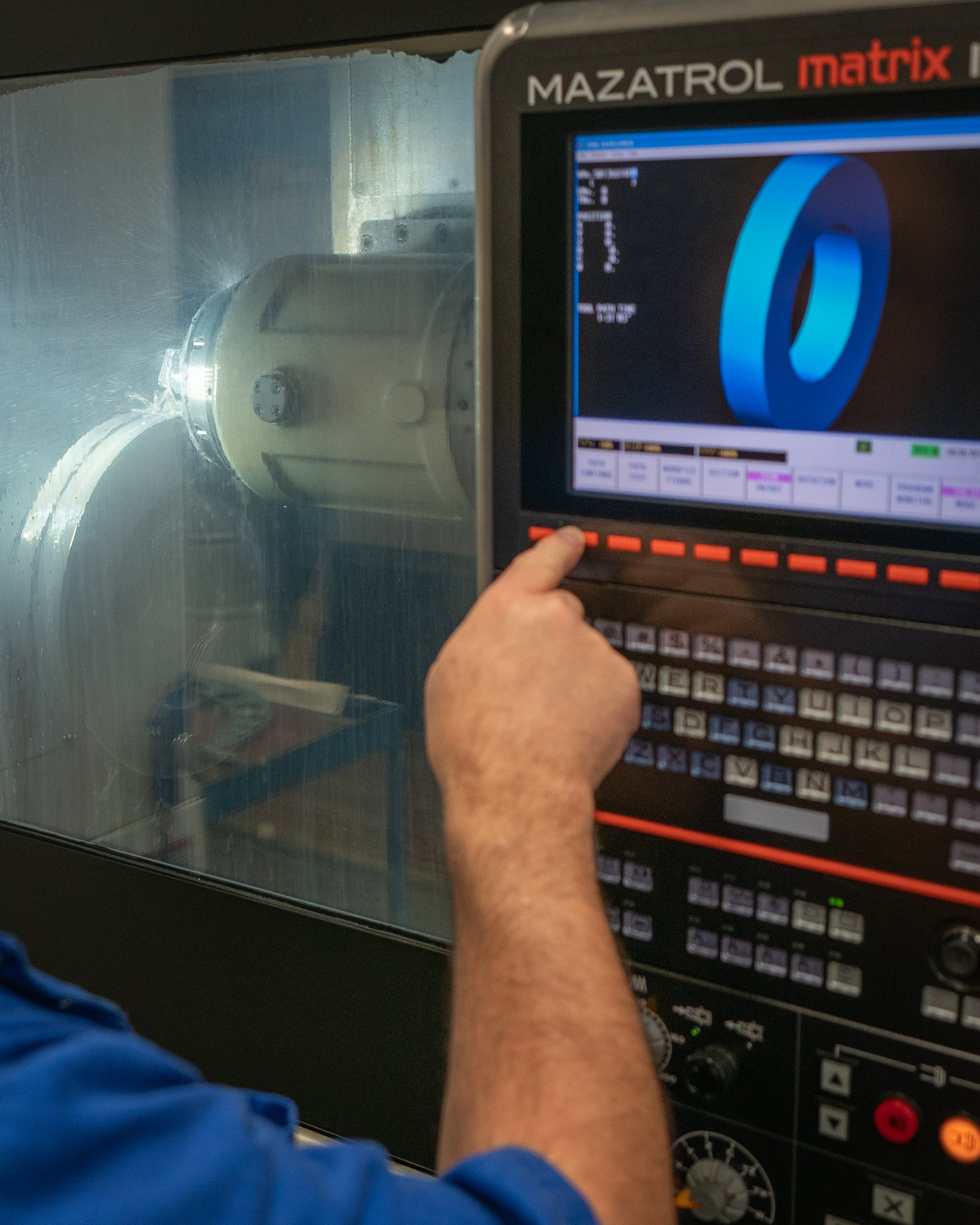

MAZAK Integrex J-400

Featuring the most powerful turning spindle motor available in this series, in combination with a high speed mill spindle, automatic tool changing, and large machining area, the J-series fills the demand for a robust, multi-tasking machine to deliver on a wide variety of production requirements.

Versatile Mill Spindle indexing (B-axis)-30 ~ 190 degrees

High-speed, high-torque milling spindle

Large true Y-axis design

Large tool magazines to reduce setup time

Programmable NC tailstock

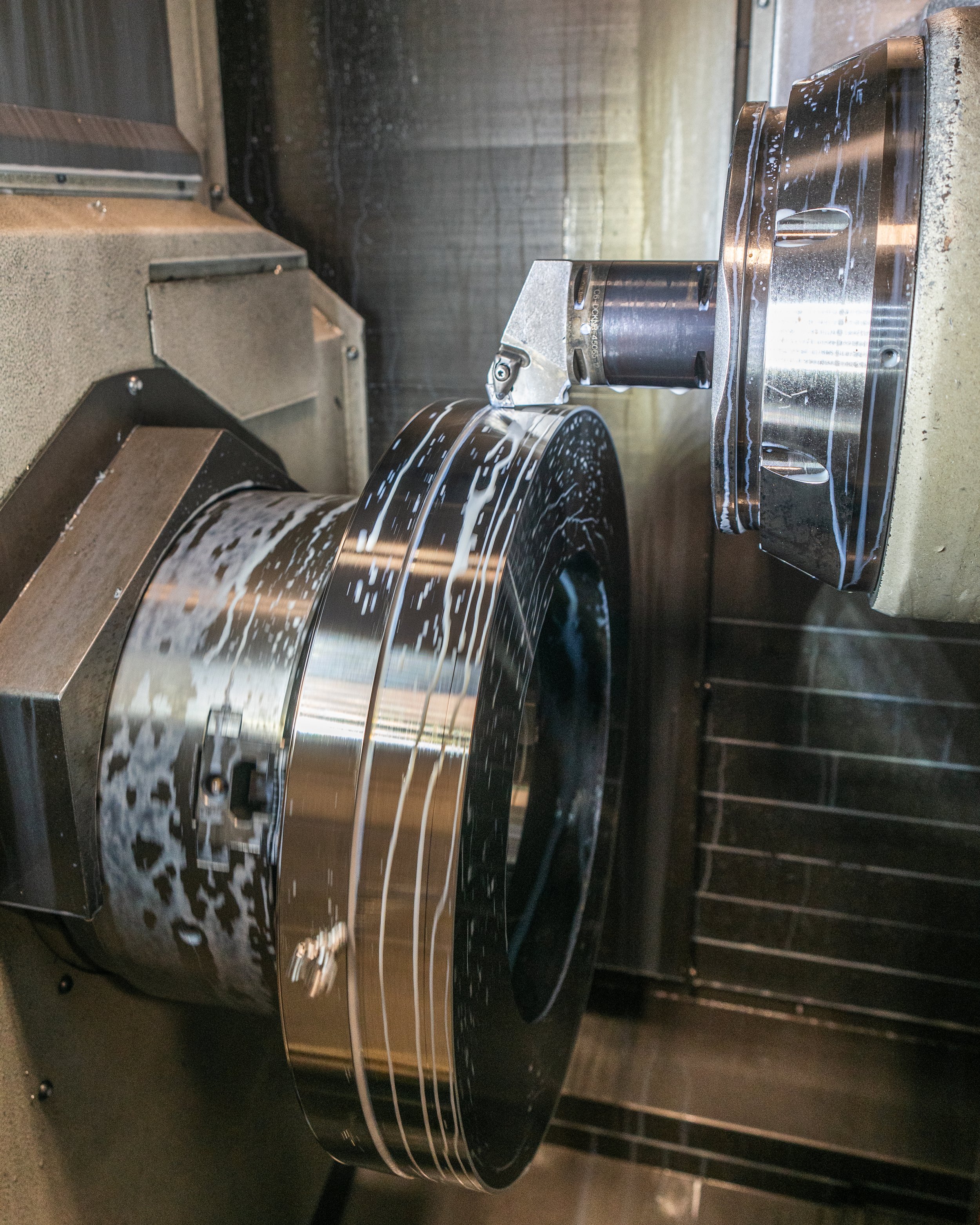

MAZAK Integrex 300 IV

The INTEGREX 300 IV delivers maximum versatility and high precision for medium to large complex parts. It combines the capabilities of a high-powered turning centre and full-function machining centre to produce parts in single setups. This machine configuration works to minimize fixtures, tools, handling and non-cut time.

Max Machining Length: 60” Max Swing: 30”

Milling spindle travel -30 ~ 210 degrees (.0001 degree min index angle)

Full C-axis contouring (.0001 degree minimum index)

Secondary spindle for completing second operations

Y travel=± 4.53″

40 tool ATC

MAZAK Integrex 300-III S

The most advanced multi-tasking machines in the world – Turning plus milling performance the same as a machining center, all in one single machine setup.

Higher productivity thanks to combining all machining processes and continuous operation from the main to second spindles.

12,000 RPM Rotary tool spindle

4,000 RPM Spindle

Simultaneous machining by both turrets reduces overall machning time